TC4191A05 Metal Impeller for Mining Slurry Pump 4/4TC

TGSL70147DPT118A49 Impeller for FGD pump, TGSL70147DPT118 A49 Impeller, 700GSL Pump Impeller

Closed impeller, slurry pump impeller, 700GSL pump wet parts,

700GSL Absorber Recycle Pump TGSL70147DPT118A49 Impeller

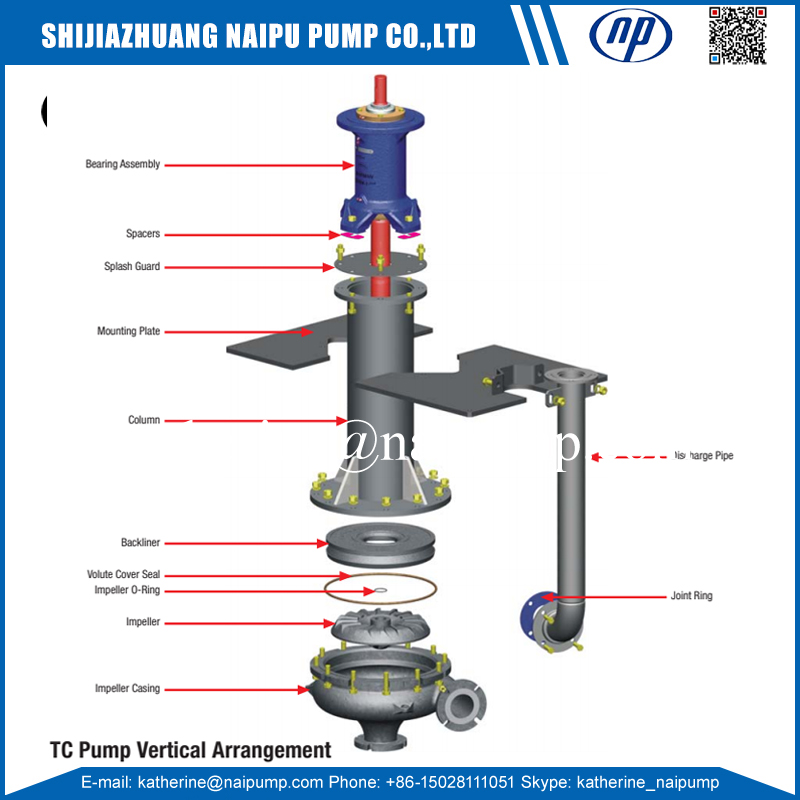

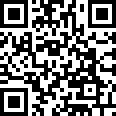

TC Pump Key Features:

• Unlined all-metal wet end is suitable for horizontal and vertical configurations

• Double suction with unique recessed open impeller design to create vortex action

• Vortex design transfers energy to the medium being pumped which enables "soft" transfer of solids to limit particle degaradation

• Equally sized inlets and outlets determine maximum particle size the pump can handle limiting potential blocking

• Hard metal fitted for longer operating life

• Large volume casing design reduces internal velocities further decreasing wear and particle degradation

GSL slurry pump using for Flue Gas Desulfurization (FGD) systems. GSL pumps have the highest efficiencies in the industry achievable throughout the life of the impeller.

The recessed impeller design, together with the large volume casing, has allowed the impeller vanes to be positioned outside of the general flowpath of the fluid. This results in the pump's large particle handling capability as well as very low particle degradation due to the limited vane interaction with the medium being pumped.

The Cyklo (TC) horizontal type hard metal wet end fitted pump range is applied in situations where non-clog or gentle pumping features of the TC are required. The vortex type priciple is applied to avoid damaging particles going through the pump.

TC2075 Shaft Sleeve, TC2028 Expeller, TC3075 Shaft Sleeve, TC4075 Shaft Sleeve

|

Impeller

|

TC4191A05

|

|

Back liner

|

TC4041-1A05

|

|

Volute

|

TC4092-1A05

|

|

|

CYKLO VORTEX SLURRY PUMPS

10/10TC Pump Wet-end Parts Codes:

|

Part Name

|

Part Code

|

Pump Model

|

Material

|

|

Impeller

|

TC25191-A05A

|

10/10 TC

|

MA05, A05A, A33, A49, A12, A51, A61

|

|

Pump Casing

|

TC25092-1-A05A

|

10/10 TC

|

MA05, A05A, A33, A49, A12, A51, A61

|

|

Back Liner

|

TC25041-1-A05A

|

10/10 TC

|

MA05, A05A, A33, A49, A12, A51, A61

|

slurry pump metal impeller, FGD pump impeller

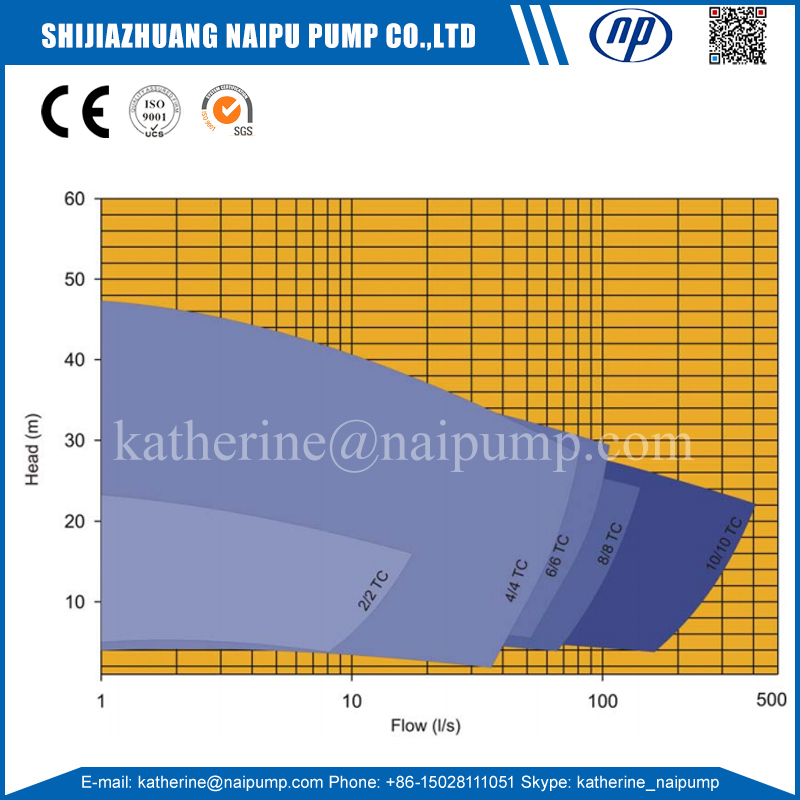

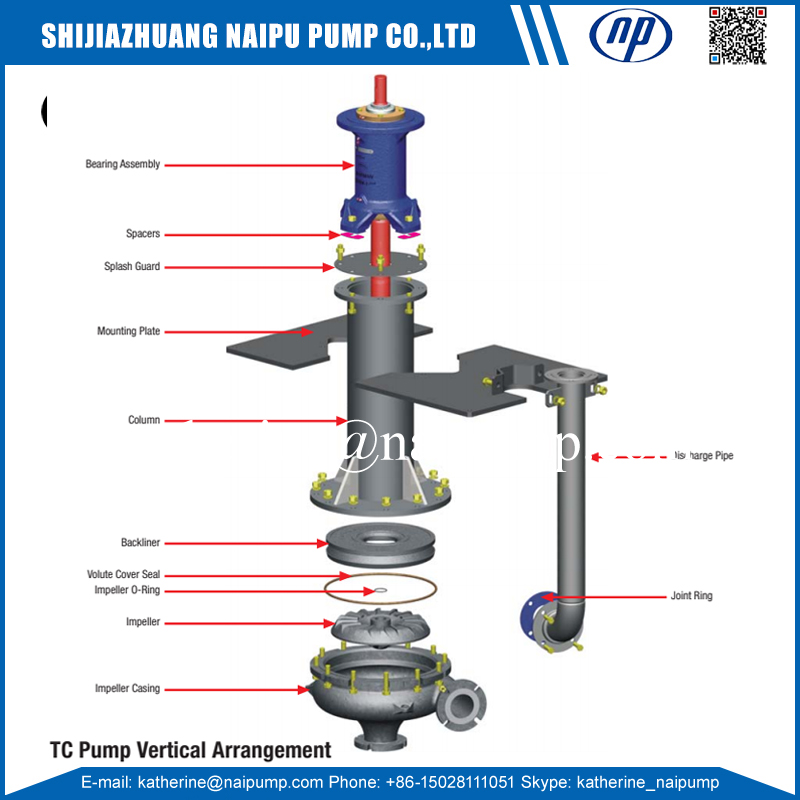

2/2 TC

3/3 TC

4/4 TC

6/6 TC

6/4 TC

8/4 TC

8/6 TC

8/8 TC

10/6 TC

10/8 TC

10/10 TC

Q1. How slurry pump works?

A: HH slurry pumps are those of cantilever, horizontal and centrifugal ones, which are widely used to transport corrosive/ abrasive and high concentration slurry in many industries.

P2. How to gurantee the quality?

A: All our pump and spare parts pass ISO 9001:2008 and CE certificate. Warranty time is 12 month except wet end parts.

P3. What information should be known if I want to get a quotation?

A: Pump working conditions, Usage , Pump Capacity, pump Head , Slurry SG, The More the Better. Please offer me the type of the used pump that working now.

P4. Manaufacturer or trader?

A: Manufacturer of couse. Our Factory located in Shijiazhuang, Hebei , China. Welcome to visit.

Q5. Your company product range?

A: Centrifugal pump, Slurry pump, Sand pump, Gravel pump, Dredging pump, Clean water pump, Sewage pump, Chemical pump, Single stage pump, Double suction pump, Industry pump, Paper pulp pump, Mud pump, Sludge pump, etc

Q6. Czas dostawy:

A: For the Common Slurry pump and spare parts , the delivery time within 7-15 days. Special material and OEM production is longer.

Any question please contact Katherine Hou freely.

+86 150281115051